Custom Epoxy Furniture: Make It Truly Your with endless Personal Expression

Share

Custom epoxy furniture has surged in popularity for its blend of natural beauty and personal expression. Unlike mass-produced pieces, a custom epoxy resin table is a one-of-a-kind creation tailored to your vision. From the swirling patterns of colored resin to the unique grains of hand-picked wood, every element can be customized. The result is more than just furniture – it’s a functional work of art that reflects your style and fits your space. In this post, we’ll explore the benefits of custom epoxy furniture, the many ways you can personalize it, and how to make it truly yours.

Why Choose Custom Epoxy Furniture?

Custom epoxy furniture offers a level of personalization and uniqueness that standard furniture simply can’t match. Here are a few key benefits of going custom with epoxy and wood:

-

Uniqueness & Personal Expression: No two epoxy tables are alike. The combination of natural wood slabs with epoxy resin means each piece has unique wood grain patterns and resin art. You get a statement piece that showcases your personality and taste – something guests won’t find in any neighbor’s home.

-

Endless Design Possibilities: You have complete creative control. Choose the wood species (walnut, chestnut, maple, etc.), resin color (from crystal clear to any pigment or even metallic swirls), and design style. Whether you envision a live-edge river dining table or a sleek modern coffee table, epoxy resin allows for endless design possibilities. You can even add personal touches like embedded stones, shells, or mementos in the resin for extra meaning.

-

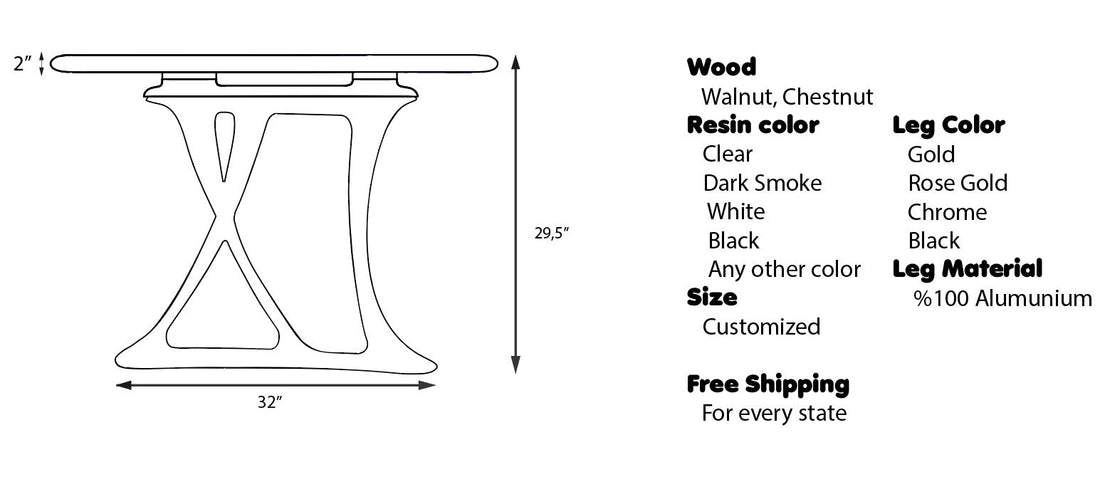

Perfect Fit for Your Space: Custom pieces are made-to-order in the exact dimensions you need. Have an awkward corner or a large dining room? Your epoxy furniture can be built to the precise size and shape that fits perfectly. You also choose leg/base designs (rustic wooden legs, modern metal frames, etc.) that complement your interior. The result is furniture tailored to both your style and your space’s layout.

-

Quality Craftsmanship: Custom epoxy furniture is typically handcrafted by skilled artisans (like the team at Gizzwood). They take care to properly cure the resin and finish the wood, resulting in a durable, long-lasting piece. Epoxy resin adds strength and water resistance to the wood, so your table is not only beautiful but also built to last. With proper care, these pieces can remain stunning for decades, truly becoming heirloom furniture.

-

Aesthetic Appeal: Let’s face it – epoxy wood furniture is downright striking. The high-gloss resin can resemble glass encasing the wood, making colors pop and wood grain glow. A custom design ensures the color scheme matches your décor or creates a bold contrast as a focal point. From ultra-modern glossy finishes to rustic live-edge charm, an epoxy piece elevates the style of any room.

How You Can Personalize Your Epoxy Furniture

One of the greatest advantages of custom epoxy furniture is the ability to tailor every detail. When you work with a custom builder like GizzWood, you can specify:

-

Wood Type & Character: Select your favorite wood species or slab. Each wood has its own character – for example, walnut offers rich dark tones, while chestnut or oak might bring lighter, warm hues. You can often choose a live-edge slab (with the natural tree edge intact) for a rustic look, or a clean-cut slab for a more polished design. The piece starts with this raw foundation, so picking a slab that speaks to you is key.

-

Epoxy Color & Effects: The resin is where creativity comes alive. You might opt for a clear epoxy that lets the wood speak for itself, or add pigments to introduce color. Popular choices include blues and turquoises for a “river table” effect (mimicking water flowing through wood), black or white resin for a modern contrast, or even vibrant gem tones for artistic flair. You can decide on transparency (transparent, translucent, or opaque) and special effects like metallic swirls, glitter, or glow-in-the-dark pigments. The epoxy can be poured in a river-like groove, in multiple sections, or across the entire surface, depending on the design.

-

Shape & Dimensions: Customize the size to fit your needs – whether it’s a large 10-person epoxy dining table or a compact epoxy coffee table for a condo living room. You also choose the shape: rectangular, round, oval, or organic natural contours. Thickness of the tabletop can be adjusted, and edges can be finished in different styles (live-edge, chamfered, or smooth edges). Every measurement, from length and width to height, is made to order.

-

Inlays & Decorative Elements: Because epoxy starts as a liquid, you can embed objects or materials into it before it hardens. This opens up lots of creative options. Some ideas include embedding pieces of crushed glass, stones, dried flowers, or even personal items like coins or family memorabilia into the resin. Love the ocean? Imagine small seashells cast in a blue resin river. The ability to add inlays means your table can literally include parts of your story or things you love, making it profoundly personal.

-

Finish & Legs/Base: Complete the design with your choice of table legs or base. Many epoxy table tops pair beautifully with metal bases – for instance, raw steel for an industrial vibe or powder-coated legs in a color that matches the resin. Alternatively, wooden legs (perhaps even made from the same wood species as the top) can create a cohesive look. You might choose sleek hairpin legs for a mid-century modern feel, a hefty trestle base for a dining table, or even custom-shaped epoxy/wood legs for a truly seamless piece. Don’t forget the finish on the wood portions: matte, semi-gloss, or glossy polyurethane, for example, to achieve the look and level of shine you prefer.

All of these options mean that when you commission a custom piece, you’re basically designing furniture hand-in-hand with the craftsman. The end result is a piece that ticks every box on your list – color, style, size, and more – reflecting your individual taste.

From Raw Slab to Stunning Centerpiece: The Custom Process

Ordering a custom epoxy piece might seem daunting, but companies like Gizzwood make it an enjoyable journey. Here’s a quick look at how a raw piece of wood transforms into a beautiful epoxy furniture masterpiece:

-

Consultation & Design: It often begins with a consultation. You share your ideas – for example, “I’d like a round coffee table with a blue resin river” – and the team provides input and expert advice. They might show you design examples or previous projects for inspiration. During this stage, you’ll discuss all the customization options (wood type, colors, size, etc.) and the budget and timeline. By the end of the design phase, you’ll have a clear plan or even sketches of what your piece will look like.

-

Selecting the Wood: Next, the artisan will help select the perfect wood slab or slabs. This could mean you choose from available stock (they may show you photos of slabs with interesting live edges or grain). For instance, if you decided on a chestnut wood table, they’ll pick a chestnut slab with the right dimensions and character. The wood is then cut or prepared as needed (trimmed to size, dried if it isn’t already kiln-dried, and cleaned up) while keeping that beautiful grain and live edge intact.

-

Epoxy Pouring & Crafting: Once the wood is ready, the real magic happens. The craftsman places the slab in a mold or enclosure and pours the mixed epoxy resin into and around the wood as per the design. This could be a single pour or multiple layers of pouring, especially if different colors or effects are desired. For example, to create a river table, the slab pieces are arranged with a gap (the “river”) between them, and epoxy is poured to fill that river gap. The resin might take a day or more to cure (harden) sufficiently. During this phase, any inlays or special effects are added. The artisan carefully watches for air bubbles and ensures the resin spreads correctly. After pouring, the piece is left to cure and solidify.

-

Finishing Touches: After the epoxy fully cures, the piece is taken out of the mold. Now it’s all about finishing. The table top is sanded down to a smooth, even surface (often through many grits of sandpaper) and then polished to bring out a stunning shine. The wood is sealed and finished (enhancing its color and protecting it). Edges are smoothed as needed while preserving any desired live-edge sections. Finally, the legs or base are attached. The completed piece undergoes a final quality check – ensuring the surface is glassy and smooth, the structure is level and sturdy, and every detail is just right. At this stage, you truly see the transformation from a raw chunk of wood to a breathtaking piece of furniture.

The transformation can be dramatic. Take a look at the example below of a custom end table creation:

Before: This raw live-edge chestnut wood slab is the starting point for a custom table. Its rough edges and natural grain patterns hint at the beauty to come, but at this stage it’s just an unfinished piece of wood.

After: The same slab has been transformed into a stunning epoxy resin end table. Crystal-clear resin fills the gaps and rivers in the wood, highlighting the grain and stabilizing the natural cracks. The once-raw slab is now a functional piece of art with a glossy finish, ready to grace a living room. This before-and-after showcases the dramatic effect of the epoxy process and skilled craftsmanship.

Attention to Detail: Epoxy Meets Wood Up Close

One of the joys of owning epoxy furniture is examining it up close and appreciating the details. The marriage of wood and resin creates fascinating visual effects that you can get lost in. For instance:

A close-up of a handcrafted walnut epoxy side table shows the impeccable detail work. The glassy epoxy resin has cured seamlessly against the live edge of the walnut wood, preserving its natural outline. You can see how the resin’s shine brings out the rich chocolate tones of the walnut and every swirling grain line. The interface between wood and resin is smooth to the touch, yet you can visually distinguish the textures – the wood’s organic patterns versus the resin’s translucent depth. Such details are a testament to quality craftsmanship. High-end epoxy furniture makers take the time to remove all bubbles and polish the surface like a mirror, so the piece looks flawless from every angle. When guests see your table up close, these are the little features that will spark conversations (“I love how you can see the knot in the wood through the clear resin!”). Each knot, curl, and pigment streak tells part of the story of your custom piece.

Designed to Suit Any Interior Style

Beyond the beauty of the piece itself, custom epoxy furniture offers incredible versatility in interior design. Whatever your decor style, you can design an epoxy piece to match or complement it:

- If you have a modern or minimalist interior, you might choose a sleek design – perhaps a table with clear or subtly tinted resin and clean straight edges. The simplicity of epoxy and wood, with hairpin metal legs, can add an artistic focal point without overwhelming a minimalist space.

- For a rustic or farmhouse vibe, a live-edge slab with a river of blue or turquoise resin can bring a bit of nature’s wonder indoors. The organic shape and vibrant resin will pop against cozy, rustic elements. Similarly, choosing a lighter wood like oak with mossy-green resin could complement a nature-themed or boho room.

-

Industrial or urban loft aesthetics pair great with epoxy pieces that have bold contrast – think dark walnut wood with black resin, mounted on chunky steel legs. This creates a chic, edgy look that fits exposed brick walls and metal fixtures.

- Love eclectic or artistic styles? Go wild with resin art in your furniture. You could incorporate bright colors or even a galaxy-inspired resin pour with swirling purples and blues. The key is, because it’s custom, you can ensure the colors tie into your room’s palette, picking up accent colors from your decor.

The takeaway is that a custom epoxy table or shelf can be made to harmonize with any design theme. By selecting the right combination of wood tone and resin color/texture, your piece will look like it truly belongs in your space. In fact, many designers use a custom wood-and-resin piece as the centerpiece of a room and then coordinate other elements around it. Whether your home is ultra-contemporary or classically traditional, there’s a way to design an epoxy furniture piece that elevates the style and ties the room together. It’s all about choosing those custom details that speak to your aesthetic preferences.

Maintenance and Care Tips (Keeping It Yours for Years)

When you’ve invested in a custom piece, you’ll want to keep it looking its best. Fortunately, epoxy furniture is relatively easy to maintain:

- **Regular Cleaning:** The smooth, non-porous epoxy surface means spills and dirt don’t penetrate. Simply wipe the surface with a soft cloth dampened with water or a gentle cleaner. There’s no need for harsh chemicals – in fact, avoid abrasive cleaners that could dull the shine.

- **Heat and Sunlight:** While cured epoxy is quite durable, it’s wise to protect it from extreme heat. Always use trivets or coasters for hot pots and mugs to prevent any heat marks. Also, if your piece has clear or light-tinted resin, prolonged direct UV sunlight can cause slight yellowing over the years. Keep your furniture away from constant direct sunlight or use UV-protective finishes if it will be near a window. (Tinted or colored resins are less susceptible to UV effects.)

- **Avoid Deep Scratches:** Epoxy is hard and scratch-resistant, but it’s not scratch-proof. Treat the surface like you would a high-end wooden table or a glass top – avoid dragging sharp objects across it. Using placemats or a soft pad for writing (if it’s a desk) will help preserve that perfect glossy finish.

- **Re-polishing:** Over time, you might notice the shine dulling slightly (especially on a heavily-used dining table). The good news is that epoxy surfaces can often be buffed back to brilliance. A professional or DIY polishing kit can remove minor scratches and restore gloss. This means your piece can always be refreshed to look like new, even years down the line.

- **Wood Care:** Epoxy is durable but don’t forget the wooden parts! They are typically sealed, but you should still treat them with care. Keep the humidity in your home moderate to prevent the wood from drying or warping. If the wood finish ever looks dry, ask your furniture maker for recommended oil or wax to recondition it (if appropriate for the finish used).

By following these simple tips, your custom epoxy furniture will maintain its beauty and integrity for many years. Part of making it “truly yours” is also caring for it like the cherished piece of functional art that it is.

Ready to Create Your Own Custom Piece?

There’s nothing quite like the experience of collaborating on a piece of furniture that is made just for you. Custom epoxy furniture allows you to unleash your creativity and enjoy a stunning result in your home. Whether you’re dreaming of a show-stopping live-edge dining table or a petite side table with personal touches, GizzWood is here to help bring that vision to life.

From initial idea to final product, the GizzWood team will work with you every step of the way. Not sure where to start? Contact us for a free design consultation – we’ll discuss your style, needs, and brainstorm the perfect epoxy furniture piece for your space. You can also explore our online gallery of custom epoxy furniture to spark ideas and see what’s possible, from coffee tables to conference tables.

Make it truly yours. With custom epoxy furniture, you’re not just buying a table or a shelf – you’re investing in a meaningful piece of art crafted to your specifications. Ready to get started on your own conversation-worthy furniture? Reach out to GizzWood today, and let’s create something uniquely you.